WHERE

DESIGN MEETS

PRECISION

Technical pattern development for

innovative performance and activewear brands

What is Studio oosm?

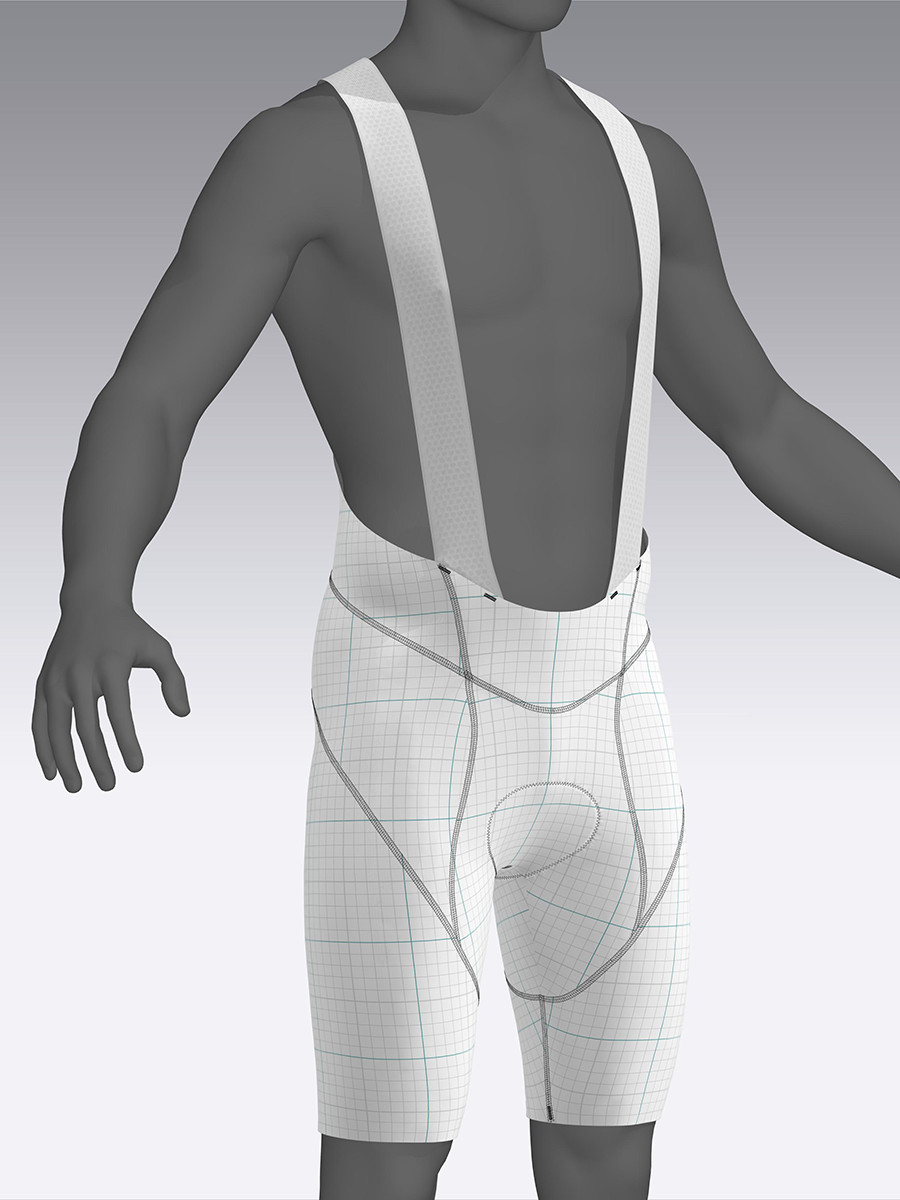

Using 3D technology, designs are visualized and tested early in the development process. This enables targeted, step-by-step adjustments before any physical samples are produced and leads to well-founded decisions in construction, fit and material behaviour.

Studio oosm supports brands that do not have their own pattern department or that want to temporarily strengthen their development with external technical expertise. In addition to pattern development, we also guide, where needed, the technical process towards production and ensure technically accurate files and clear communication with production partners.

We collaborate with brands that invest in quality, precision and sustainability, and that understand a strong product starts with a well-considered technical foundation.

Want to know more about what we can do for your project? We would be happy to discuss it

What we do

How we work

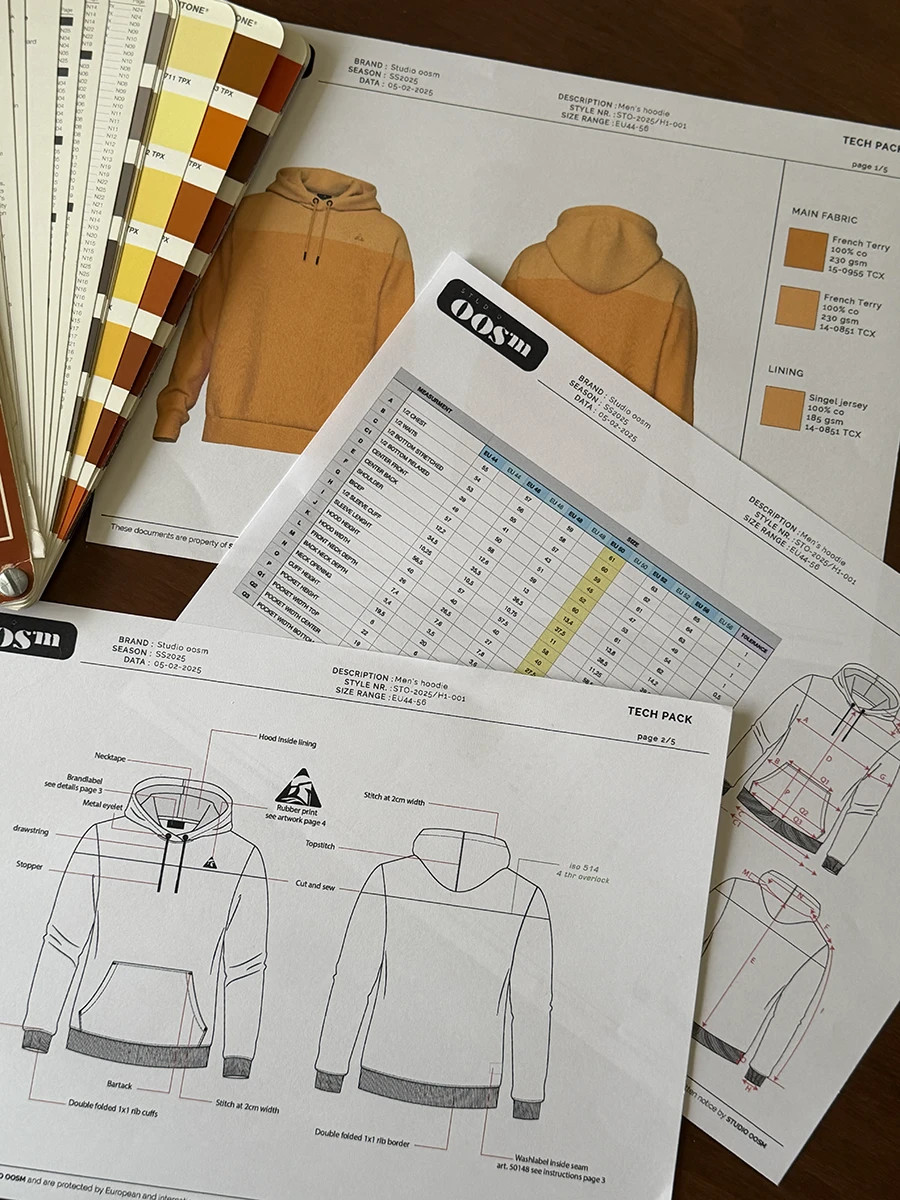

Studio oosm works as an external development partner for brands that invest in technical quality. Pattern development is approached as a structured, step-by-step process, with a focus on functionality, movement, and precision.

During an initial consultation, specific needs are discussed and together the relevant steps for the project are defined. Before the project starts, a clear and transparent quote is provided so that expectations and agreements are fully understood.

Step 1 - Analysis & context

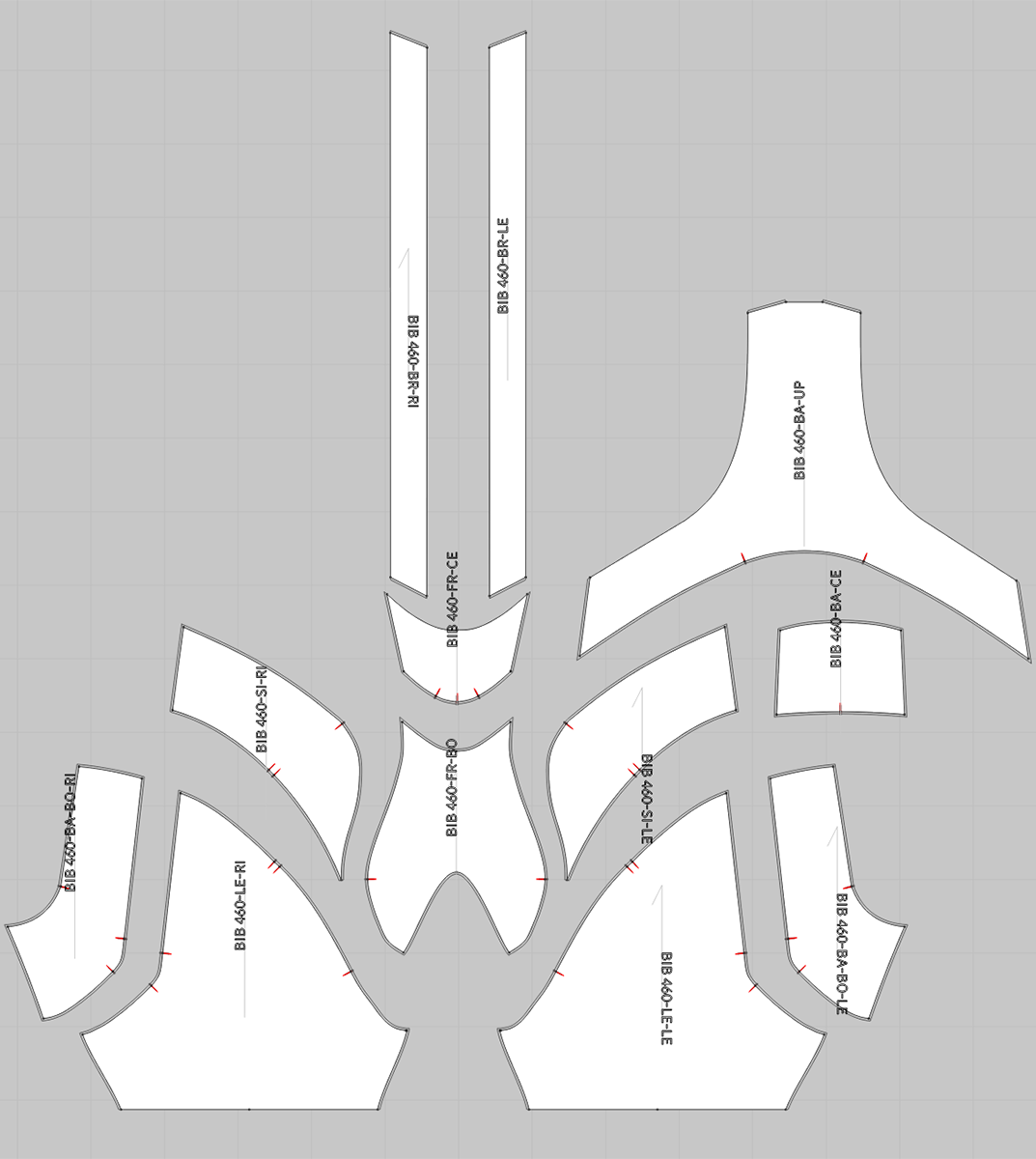

Every development starts with a thorough analysis. Before building patterns, the intended use, body movement, material properties and technical requirements are defined. This step forms the basis for well-founded development decisions.

Step 2 - Pattern development

Based on the analysis, new patterns are developed or existing patterns are optimised. Through fitting sessions, the fit is assessed and refined.

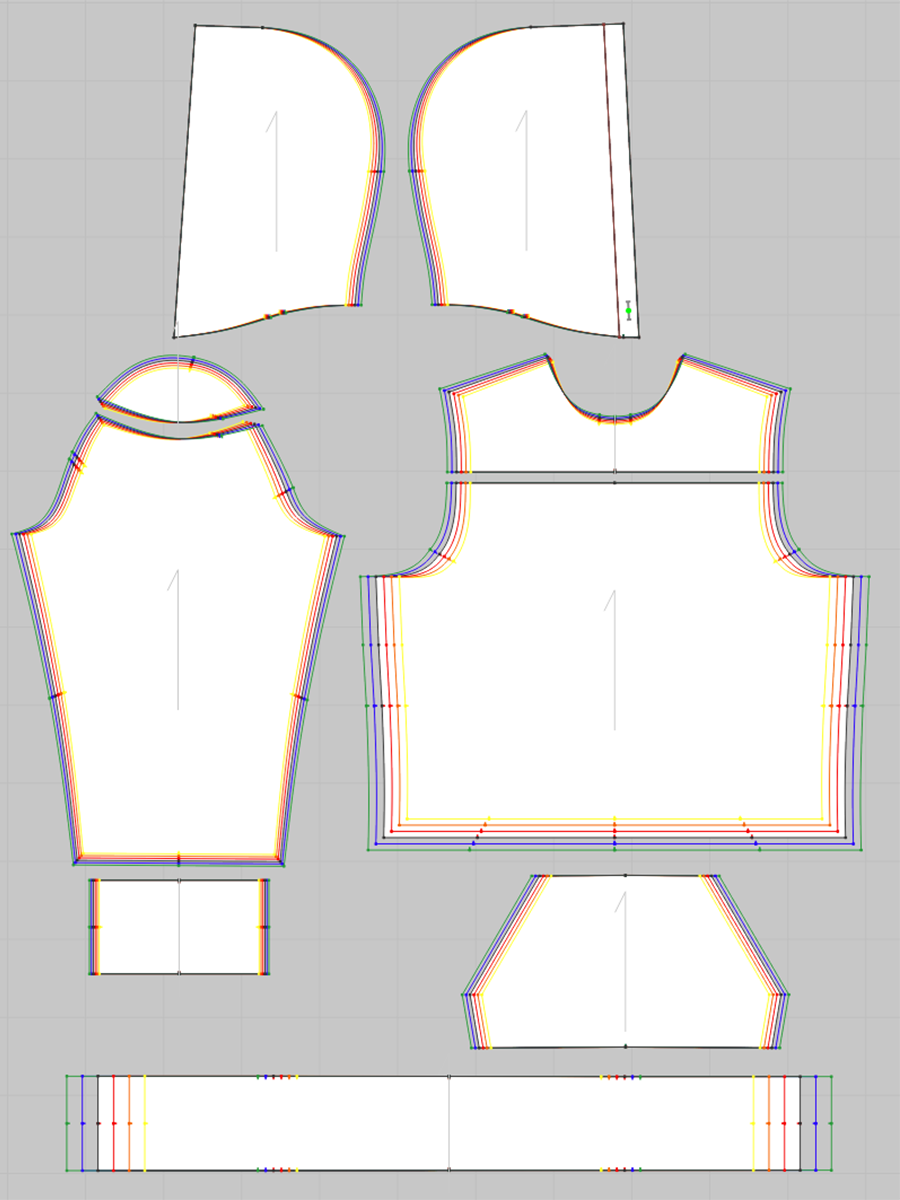

Step 3 - 3D visualisation (optional)

With the help of 3D technology like CLO 3D, patterns can be visualized and tested early in the development process. This makes it possible to evaluate without immediately producing physical samples, which can significantly speed up the process. 3D supports well-considered decisions at both technical ,functional and design level.

Step 4 - Refinement & production preparation

The pattern is graded, technically optimised and prepared for production. Accuracy and precision are paramount here so that production runs as smoothly as possible.

Step 5 - Technical support (optional)

If desired, technical transfer to production is supported. This includes technically accurate files with clarification of construction details and communication with production partners.

Unsure whether your project fits our way of working?

Then we would be happy to discuss it together.